Application of plate heat exchanger in radiant heating and cooling

Radiation heating and cooling air conditioning systems have been used and developed in Europe and North America for many years. Unlike traditional convection air conditioning systems, radiative heat and heat transfer systems account for more than 50% of total heat exchange. The air conditioning system based on low-temperature radiation heat transfer works by inputting cold water of about 18 °C into the end of the radiation in summer to form a cold radiating surface; in winter, it provides hot water of about 45 °C to the end of the radiation to form a heat radiating surface, relying on Radiant heat exchange with the human body, furniture and the rest of the enclosure is cooled (heated). If the temperature of the hot and cold water supplied by the cold heat source is too low or too high to meet the radiation end temperature requirements, the plate heat exchanger or other methods (such as water mixing) are usually used to achieve the temperature of the cold (hot) medium. Claim.

First, the application in radiant cooling

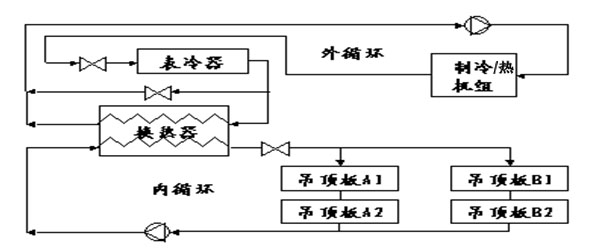

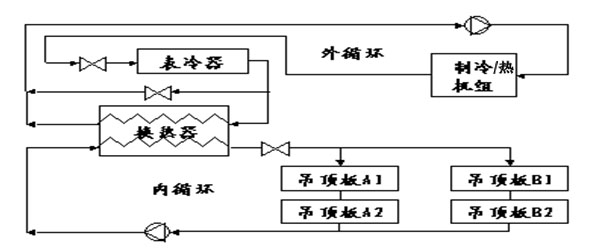

When radiant cooling, the temperature of the cold water in the end of the radiation should not be too low, otherwise it will easily produce condensed water at the surface of the radiation, causing condensation. Generally, the method of controlling the temperature of the cold water inlet of the radiation end is adopted, so that the surface temperature of the radiation plate is higher than the air dew point temperature by 1 to 2 ° C to prevent condensation. The chilled water temperature (16-18 °C) used in radiant cooling systems is usually higher than conventional air conditioning systems (7 °C). The higher cold water temperature provides a choice for natural cold sources such as evaporative cooling (6-8 ° C), but It also makes the chilled water produced by the conventional chiller (the supply and return water temperature is 7/12 °C) can not directly meet the requirements of the radiant cooling system for the cold water temperature. Generally, the high temperature required for radiant cooling can be obtained by the method of mixing water. Cold water, but in order to prevent the cold water from directly entering the sensible heat exchange end (especially the capillary) and causing scale on the inner surface of the heat exchanger to block, the high-efficiency plate heat exchanger can be used to carry out the countercurrent heat exchange of the cold water produced by the chiller. Then send it to the sensible heat end. The inlet water temperature commonly used for sensible heat at the time of radiant cooling is 16 to 18 ° C, and the return water temperature is generally 21 to 23 ° C.

Second, the application in radiant heating

The application of plate heat exchanger in low temperature radiant heating is divided into two types: water-water heat exchange condition and steam-water heat exchange condition. When steam is used as the heat source, the steam must be low-pressure saturated steam. The pressure commonly used in engineering is: gauge pressure 0.3MPa or gauge pressure 0.4MPa, the steam temperature at this time is 144 ° C and 152 ° C. When hot water is used as the heat source, the hot water supply back water temperature is generally 95/70 °C. In radiant heating, the temperature of the hot water supplied to the end of the radiation should not be too high, generally not exceeding 60 ° C. The main reasons are:

1. Due to the large radiation area, the water temperature does not need to be too high to meet the room temperature design requirements;

2, the human body comfort requires the ground temperature can not be too high;

3. At higher water temperatures, the life of plastic pipes commonly used in radiant heating is greatly reduced. According to the different requirements of building insulation and occupants, the ground temperature is usually controlled within the range of 24 to 30 °C. Excessive temperature affects comfort and causes unnecessary waste. If the temperature is too low, heating requirements are not met.

In recent years, the state's requirements for building energy conservation have been continuously improved, and the degree of insulation of the envelope structure has become better and better, which has led to a continuous decrease in the actual use of water. Under the premise of common pipe diameter and pipe spacing, the actual required inlet water temperature is often lower than 50 °C. When the outdoor temperature is not too low, the inlet temperature of 30-40 °C can already have obvious heating effect. The inlet and outlet water temperature commonly used in low temperature radiant heating systems is usually 45/35 °C.